Custom Packaging Solutions

Environmentally Friendly • 100% Recyclable • Durable • Made in the USA

The CoolSeal Difference: Smarter Packaging, Greater Savings

- Most packaging suppliers will sell you a box. We provide a solution. At CoolSeal, we don’t just cut costs, we uncover hidden savings across your entire organization. Our approach goes beyond delivering a simple container. We engineer smarter packaging that reduces waste, streamlines operations, and adds real value where you least expect it.

Packaging: The Invisible Giant

Packaging is the world’s largest industry, yet it gets no respect. It’s the Rodney Dangerfield of business—"it gets no respect". Consider this: everything you see, touch, wear, eat, or use has been packaged multiple times before reaching you. Companies invest heavily in product development but often overlook the critical role of packaging in protecting and presenting their innovations. That’s where we come in.

Full-Service, End-to-End Packaging Solutions

Unlike other suppliers, CoolSeal is fully integrated. From our Perrysburg, Ohio facility, we extrude the polypropylene sheet, print, die-cut, and finish each box to your exact specifications. We offer both returnable (multi-use) and recyclable (single-use) packaging, including options for those looking to purchase crop boxes in bulk, ensuring the right solution for your industry. Need a standard option? We provide industry-specific packaging for food, pharmaceuticals, automotive, construction, horticulture and beyond—engineered as fully recyclable alternatives to Styrofoam and waxed corrugated for cold-chain logistics.

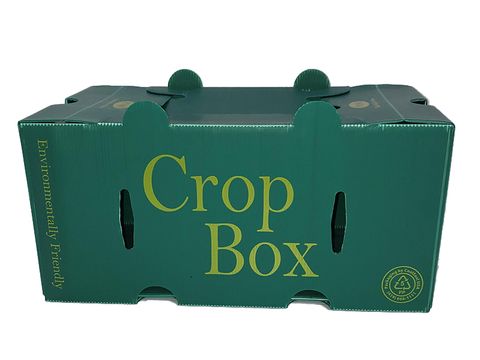

Crop Box Bulk Purchase Information

Important to Note: Standard Crop Boxes are Polypropylene (PPS) with UV Ink. The boxes are shipped flat for easy assembly in the field. The minimum order quantity is 1 bundle, sold in bundles of 25. Pricing does not include freight charges, freight is FOB at our dock in Perrysburg, OH. Customization is available with a minimum order quantity of 1200 and pricing is determined by scope.

1/2 Bushel Size

Size: 16"L x 9"W x 7.5"H

Quantity: 100 or Less | Cost: $6.32 each | Shipping: UPS

Quantity: 125 to 575 | Cost: $5.78 each | Shipping: UPS or LTL Carrier

Quantity: 600 or More | Cost: $5.27 each | Shipping: LTL Carrier

3/4 Bushel Size

Size: 16"L x 9"W x 11.5"H

Quantity: 100 or Less | Cost: $6.88 each | Shipping: UPS

Quantity: 125 to 575 | Cost: $6.32 each | Shipping: UPS or LTL Carrier

Quantity: 600 or More | Cost: $5.73 each | Shipping: LTL Carrier

1-1/9 Bushel Size

Size: 17.5"L x 11.75"W x 11.675"H

Quantity: 100 or Less | Cost: $7.44 each | Shipping: UPS

Quantity: 125 to 575 | Cost: $6.91 each | Shipping: UPS or LTL Carrier

Quantity: 600 or More | Cost: $6.29 each | Shipping: LTL Carrier

The Benefits of Sealed Edge Packaging

CoolSeal’s unique sealed-edge technology provides unmatched performance across multiple industries. By sealing the edges of our 100% recyclable fluted polypropylene (PP5) packaging, we offer significant advantages that set us apart from traditional materials:

1. Superior Insulation

Sealed-edge packaging traps air within the flutes, creating a built-in insulation effect. This enhances temperature retention, making our boxes the perfect choice for chilled and perishable goods, such as seafood and pharmaceuticals. Our customers benefit from extended freshness and improved cold-chain reliability.

2. Unrivaled Hygiene & Contamination Prevention

Unlike cardboard or polystyrene, our sealed edges prevent contaminants, moisture, and debris from entering the fluted structure. This barrier ensures a higher level of hygiene, making it ideal for food-grade and medical applications. Additionally, polypropylene is waterproof, ensuring full protection in moisture-rich environments.

3. Enhanced Strength & Durability

Sealing the edges reinforces the structural integrity of our packaging, reducing damage during handling and transit. The waterproof and impact-resistant properties make it an excellent solution for closed-loop, returnable, or reusable packaging systems where longevity and performance matter.

4. Customization & Design Versatility

As a full-service manufacturer, we tailor every packaging solution to your exact specifications. Whether you need custom dimensions, branded designs, enhanced protection, or bulk manufacturing, our sealed-edge technology delivers a versatile, sustainable alternative to conventional materials.

Want to see the difference for yourself?

Request a free sample, and we’ll send you one to experience the superior performance of CoolSeal’s expert packaging firsthand.

Advanced Manufacturing Capabilities

Our Perrysburg, Ohio facility spans 78,000 square feet, with an additional 33,000 square feet of warehouse space, enabling us to handle high-volume production with the efficiency and precision needed for bulk orders.

Extrusion

We extrude polypropylene sheets in 2mm (450 gsm) through 10mm (2000 gsm) thicknesses, which have become North American standards. We also offer custom weights to meet project-specific requirements.

Our extruder features a usable web width of 105” across the flutes, with virtually unlimited run length.

We extrude approximately 1,500 pounds per hour, totaling around 9 million pounds per year.

As part of our commitment to sustainability, we strive for zero residual waste, recycling 100% of our scrap—amounting to 2 million pounds annually.

Flexographic Printing and Die Cutting

Our maximum sheet size is 66” x 80”, allowing us to process up to 3,000 sheets per hour. If multiple blanks can be cut from a single sheet, this means up to 12,000 parts per hour.

Die Cutting

We operate eight high-speed die cutters of various sizes, ensuring the most competitive production process for any project:

Young Shin 190 Heated Platen Die Cutter – 3,000 impressions per hour, 70” x 54” platen size, handling thicknesses from 2mm to 8mm.

Young Shin 170 Heated Platen Die Cutter – 3,000 impressions per hour, 66” x 46” platen size, handling thicknesses from 2mm to 8mm.

Die Cut Redline Heated Platen Die Cutter – 3,000 impressions per hour, 70” x 54” platen size, handling thicknesses from 2mm to 8mm.

Ward Rotary Die Cutter – 3,000 impressions per hour, 66” x 80” die cut size, handling thicknesses from 2mm to 8mm.

JackRabbit Heated Platen Clamshell Die Cutter – Large format manual die cutting up to 48” x 96”, handling thicknesses from 2mm to 8mm.

Crest Heated Platen Clamshell Die Cutter – Medium format, 60” x 48” die cutting size, handling thicknesses from 3mm to 8mm.

Vicki Rotary Die Cutter – 1,500 impressions per hour, 66” x 114” die cut size, handling thicknesses from 2mm and up.

Pioneer Roller Press – Highly flexible manual die cutter with virtually no size restrictions.

Lamination

Our laminator can adhere fabrics to virtually any plastic thickness with a maximum width of 52”, accommodating any length required by your project.

Services Our Boxes Enhance:

From agriculture to automotive, CoolSeal packaging is trusted across a wide range of industries that require cleanliness, durability, and efficiency in bulk shipments and transit.

Agricultural / Produce

Our reusable produce boxes allow Community Supported Agriculture (CSA) programs the ability to provide consumers the opportunity to enjoy organic, seasonal crops like fruit, vegetable and herbs while utilizing environmentally friendly packaging solutions.

Automotive

CoolSeal USA has been a provider of plastic corrugated sheet goods, pads and laminated plastic corrugated to fabricators within the automotive returnable packaging industry. Whether it is raw material in stock sheet, custom sizes, or printing or die cutting that is required, we can help!

Construction

In the construction world, we know how valuable it is to cut down on costs. CoolSeal USA can help with having multiple sizes and thicknesses of reusable sheet goods available to utilize for your next project whether it be protecting finished flooring or erecting temporary barriers.

Education

From our extrusion line to your facility, CoolSeal polypropylene is one of the most “fabricatable” products in the world. The versatility of this 100% sustainable, 100% recyclable product allows us and our customers to shape and form this material for use in all sorts of educational applications, including: sneeze guards, testing cubicles and storage trays.

Fresh Seafood

Our seafood boxes have been designed specifically as a replacement for wax corrugated and Styrofoam packaging within the fresh and frozen protein markets. 100% recyclable and eco-friendly, our packaging is lightweight, durable, hygienic and easily assembled. Shipping flat to the processor, our packaging saves on space as well as freight costs and stands out from traditional industry solutions.

Horticulture

Whether it is bumblebee hives or tree guards, CoolSeal USA has the solution. With our lightweight, durable and weather-proof boxes, you can be sure that these boxes are ideal for open field horticulture and nature's pollinators.

Meat & Poultry

Waxed corrugated boxes have been the industry standard in the market but our CoolSeal polypropylene boxes are quickly taking market share. The advantages of our boxes just make sense … lightweight, durable, hygienic and moisture proof. Our boxes ship flat, are easily erected without staples and are 100% recyclable.

Pharmaceutical

Are you looking for a fiber free, moisture resistant, durable solution? Need partitions, trays or master packs? Our polypropylene boxes are fully customizable for the sustainable solutions you require.

Recreation

Our polypropylene sheets have been utilized for two dimensional decoys, archery / shooting targets and temporary hunting blinds in the past, but only your imagination knows the potential use of our sheets going forward. We can help you make your idea come to life.

Sustainability with a Competitive Edge

- Recyclability is built into every box we produce. Whether your packaging

- is reusable or single-use, it retains value beyond its primary function—offering a sustainable, cost-effective alternative to traditional materials.

Experience + Innovation = Better Packaging

We’re not here to claim we’re better—we simply are. Our solutions are guided by logic, common sense, and decades of experience. Backed by the $5 billion Inteplast Group, we have the resources and expertise to handle any packaging challenge.

The biggest objection we hear? “This will never work.” The biggest feedback we receive? “You were right—why didn’t we do this sooner?” Let’s talk about how we can transform your packaging strategy today.